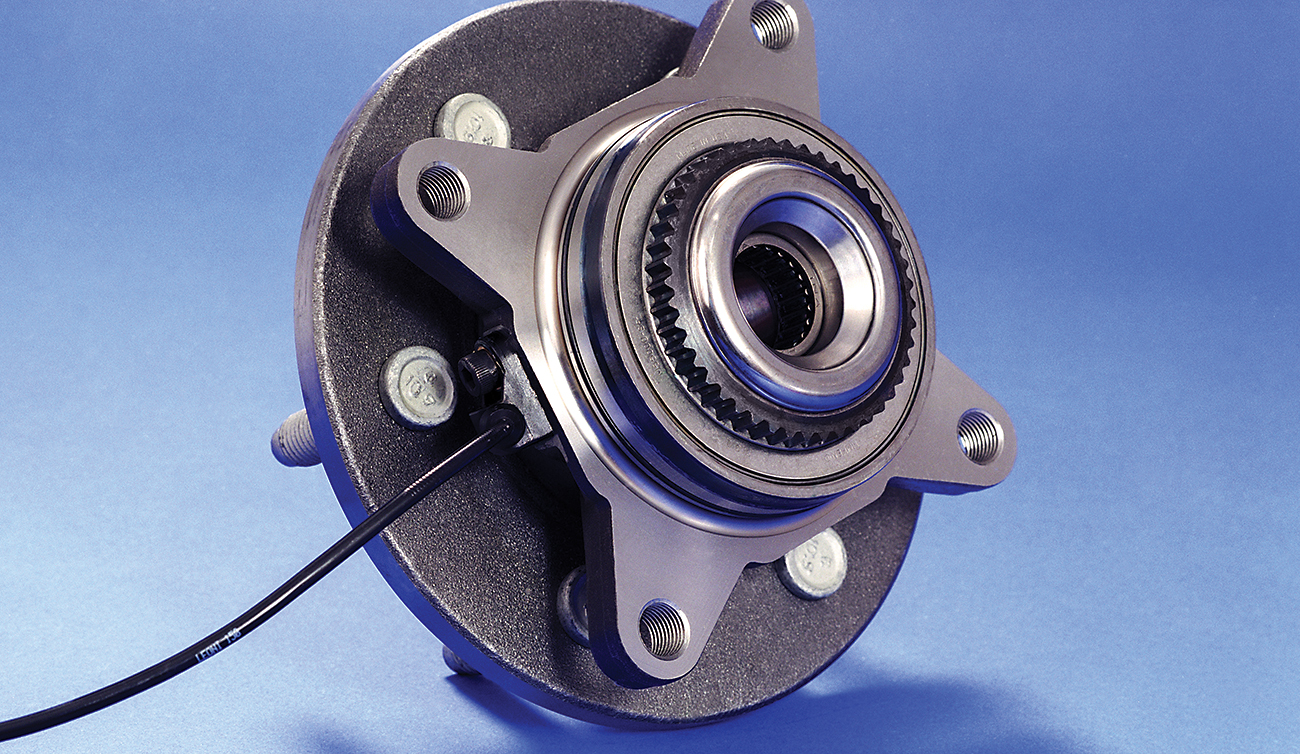

The wheel hub and bearing assembly is a critical part of your vehicle’s suspension and drivetrain. The hub houses the wheel bearings, which allow the wheels to spin freely while supporting the vehicle’s weight and maintaining precise alignment with the chassis. Without properly functioning hubs and bearings, your vehicle would experience friction, vibration, and instability, which can negatively impact handling, braking, and tyre longevity.

Wheel bearings are precision-engineered components designed to handle radial and axial loads from vehicle weight and cornering forces. Over time, however, bearings are subject to wear due to heat, friction, contamination, and exposure to water, salt, or road debris. As they degrade, symptoms such as humming, grinding, or rumbling noises often become noticeable, particularly at higher speeds. A worn hub or bearing can also trigger ABS or traction control warning lights, as these systems rely on accurate wheel rotation data.

Wheel hubs themselves can also suffer from corrosion, impact damage, or stress cracks, particularly after accidents or rough driving conditions. Compromised hubs may cause wobbling wheels, uneven tyre wear, or even complete wheel separation in extreme cases. Because the wheel hub and bearing assembly is integral to both suspension and drivetrain function, early detection and repair are essential for safety and reliability.

At Tinspol Motors, our technicians perform thorough inspections of wheel hubs and bearings during routine service or when symptoms appear. We check for play in the bearing, measure rotational smoothness, and inspect the hub assembly for signs of wear, damage, or corrosion. We also examine ABS sensors and related components to ensure proper functionality. By identifying early signs of wear, we prevent more serious failures that could compromise vehicle safety.

When replacement is required, we use high-quality OEM or performance-grade hubs and bearings designed for your specific vehicle. Our technicians ensure precise installation, torque specifications, and lubrication, restoring smooth rotation and proper wheel alignment. After installation, we test drive the vehicle to confirm quiet operation, stable handling, and accurate ABS and traction control performance. Maintaining these components in optimal condition improves driving safety and prolongs the life of tyres, brakes, and suspension parts.

Preventive maintenance for wheel hubs and bearings includes keeping the undercarriage clean, avoiding water and mud ingress, and addressing unusual noises promptly. Periodic suspension inspections, particularly on vehicles frequently driven on rough roads or with heavy loads, help identify early wear and prevent costly repairs.

Symptoms of failing hubs or bearings include humming, grinding, or rumbling noises, wheel wobble, uneven tyre wear, vibration in the steering wheel, and warning lights for ABS or traction control. Ignoring these signs can lead to dangerous situations, including reduced braking efficiency and compromised handling, which affect the safety of the vehicle and its occupants.

At Tinspol Motors, we combine advanced diagnostic tools, hands-on expertise, and high-quality replacement parts to ensure your wheel hubs and bearings perform flawlessly. Our team ensures smooth wheel rotation, precise handling, and reliable braking performance. Trust Tinspol Motors to keep your wheels rotating safely and efficiently, delivering a smooth, controlled, and confident driving experience every time.